Evolution of Manufacturing

Manufacturing has undergone a remarkable transformation in recent decades. Traditional manual processes have been replaced with advanced, technology-driven production methods that improve efficiency, quality, and scalability. Modern manufacturing emphasizes precision, innovation, and speed, enabling companies to deliver high-quality products at competitive costs.

Smart factories have become the hallmark of contemporary manufacturing. These facilities leverage IoT-enabled machines, real-time data analytics, and automation to streamline workflows and reduce human error. By monitoring production processes digitally, manufacturers can identify inefficiencies, anticipate equipment failures, and optimize resource utilization.

The global competitive landscape also demands flexibility. Manufacturers must respond quickly to changing customer preferences, regulatory requirements, and market fluctuations. Those that embrace advanced manufacturing technologies can produce customized products at scale while maintaining cost efficiency.

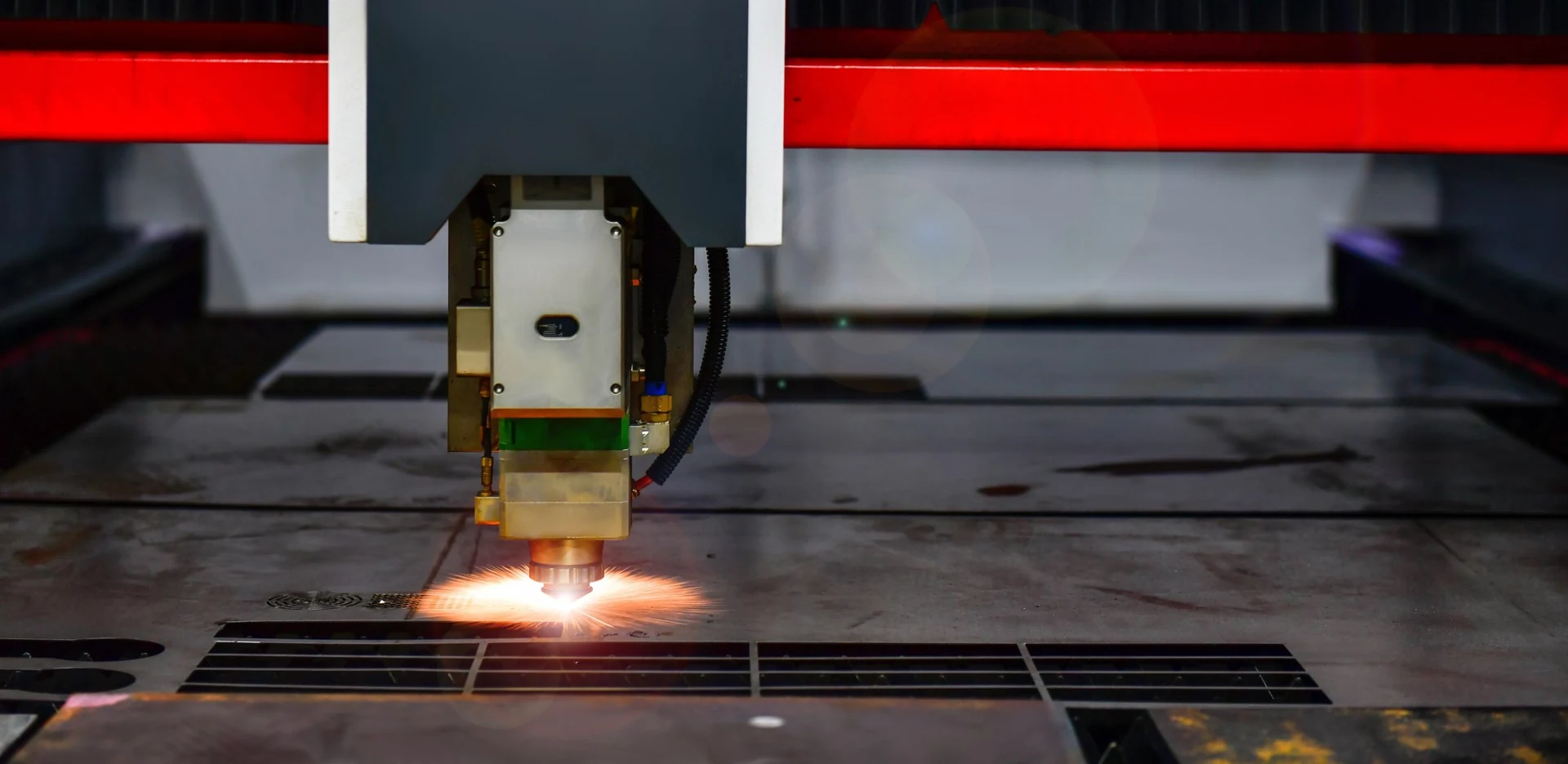

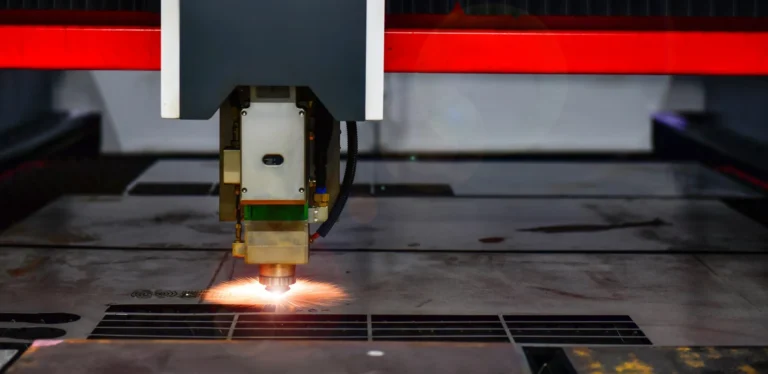

Modern Manufacturing Techniques

-

Additive Manufacturing (3D Printing): 3D printing enables rapid prototyping and the production of complex components that traditional methods cannot achieve. It reduces material waste, shortens development cycles, and allows for highly customized solutions.

-

Lean Manufacturing: Lean principles focus on eliminating waste, improving process flow, and maximizing value. From inventory optimization to continuous process improvement, lean manufacturing helps companies achieve operational efficiency.

-

Advanced Robotics: Industrial robots perform repetitive, dangerous, or precision-based tasks with high reliability. Coupled with AI, these robots adapt to changing production requirements, improving overall throughput and consistency.

-

AI-driven Production Planning: Artificial intelligence analyzes historical data and real-time metrics to optimize production schedules, predict demand, and reduce downtime. Predictive analytics help companies plan inventory, allocate resources, and minimize operational risks.

Benefits of Modern Manufacturing

-

Enhanced Productivity: Automation and advanced workflows reduce production times, increase output, and lower operational costs.

-

Improved Product Quality: Consistent processes, real-time monitoring, and precise automation minimize defects and maintain high-quality standards.

-

Faster Time-to-Market: Rapid prototyping and flexible production allow manufacturers to launch new products quickly and respond to market demands.

-

Cost Efficiency: Lean practices, energy-efficient equipment, and automation reduce waste, labor costs, and production expenses.

Best Practices for Manufacturers

-

Invest in Employee Training: Skilled workers are essential for operating advanced machinery, interpreting data, and managing automated workflows. Continuous training ensures efficiency and reduces errors.

-

Integrate IoT Devices: Sensors and connected systems enable real-time monitoring, predictive maintenance, and data-driven decision-making.

-

Regular Process Evaluation: Reviewing workflows, production metrics, and operational KPIs allows manufacturers to identify inefficiencies and implement continuous improvements.

-

Prioritize Sustainability: Sustainable manufacturing practices, such as energy-efficient machinery, waste reduction, and eco-friendly supply chains, enhance reputation and reduce costs.

Future of Manufacturing

The future of manufacturing lies in smart, flexible, and sustainable operations. Industry 4.0 technologies, including AI, IoT, and robotics, will continue to revolutionize production. Manufacturers that integrate these technologies with workforce expertise and sustainable practices will achieve superior efficiency, agility, and competitiveness.