Understanding the Modern Industrial Landscape

The industrial sector is experiencing a profound transformation, driven by rapid technological advancements, globalization, and increasing environmental and regulatory demands. For companies operating in this space, adapting to these changes is no longer optional—it’s a strategic necessity. Businesses that remain static risk falling behind competitors who embrace innovation and efficiency.

Industrial operations today are increasingly data-driven. Digital technologies, such as IoT, artificial intelligence, and machine learning, allow organizations to monitor processes in real time, predict maintenance needs, and optimize production efficiency. These innovations are creating “smart factories,” where operations are automated, responsive, and highly efficient.

Sustainability is another critical driver shaping modern industry. Stakeholders now expect companies to adopt environmentally responsible practices, reduce carbon emissions, and design products with minimal ecological impact. Those that prioritize sustainability gain a competitive advantage, as consumers and investors increasingly value green initiatives.

Globalization has also reshaped industry. Companies can source raw materials from multiple continents, access international markets, and operate production facilities worldwide. However, this also exposes them to supply chain risks, geopolitical tensions, and fluctuating costs. Companies must balance global opportunities with operational resilience and strategic planning.

Key Industrial Trends

-

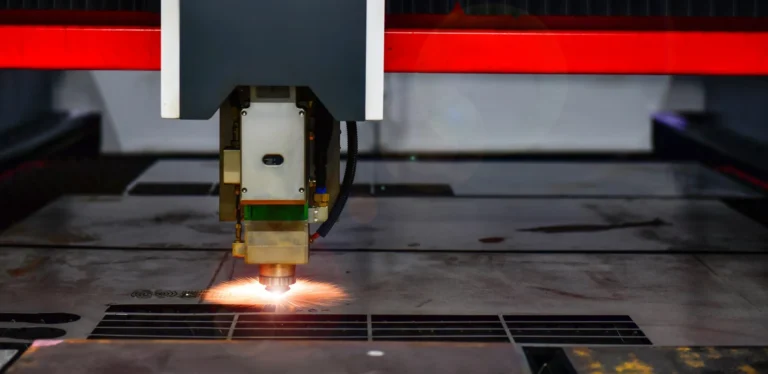

Automation and Robotics: The rise of automation is transforming production lines. Robots now perform repetitive or dangerous tasks with high precision, improving output and minimizing errors. Automation also frees human workers to focus on strategic and analytical tasks, enhancing overall productivity.

-

Digital Transformation: The integration of IoT, AI, and advanced analytics is enabling predictive maintenance, real-time monitoring, and process optimization. Digital twins—virtual replicas of physical operations—allow companies to simulate scenarios, improve efficiency, and reduce downtime.

-

Sustainability Practices: Industries are increasingly adopting green technologies, including renewable energy sources, energy-efficient machinery, and waste reduction strategies. Companies are also integrating sustainable supply chain practices, ensuring materials and processes meet environmental standards.

-

Global Supply Chain Shifts: The COVID-19 pandemic exposed vulnerabilities in global supply chains. Organizations are now diversifying suppliers, using regional hubs, and building flexibility into inventory management to reduce risk.

Challenges Facing Industries Today

Despite the opportunities offered by technology and globalization, industries face several significant challenges:

-

Rising Energy Costs: Energy-intensive operations face increasing costs due to global price fluctuations and stricter environmental regulations. Companies must find innovative ways to reduce energy consumption.

-

Labor Shortages: The industrial sector struggles with a shortage of skilled labor, as experienced professionals retire and younger workers often lack technical expertise. Workforce training and reskilling programs are essential.

-

Technological Investment: Rapid technological changes require continuous investment in machinery, software, and employee skills. Companies must carefully balance costs with long-term benefits.

-

Regulatory Compliance: Adhering to increasingly complex safety, environmental, and operational standards adds additional operational pressure.

Case Studies in Industrial Innovation

Leading industrial companies are embracing these trends successfully:

-

Siemens AG implemented digital twin technology across multiple production lines, allowing predictive maintenance and a 20% reduction in downtime.

-

Toyota applies lean manufacturing principles combined with automation to reduce waste while maintaining high-quality standards.

-

Unilever has committed to achieving net-zero emissions in production facilities by 2039, demonstrating that sustainability can align with profitability.

Future Outlook

The industrial sector’s future is characterized by innovation, adaptability, and sustainability. Companies that adopt digital technologies, optimize supply chains, and implement eco-friendly practices will gain a decisive advantage. Emerging trends, such as AI-powered analytics, predictive maintenance, and blockchain-enabled supply chain tracking, will further shape industrial operations.

Organizations that proactively prepare for these changes—investing in technology, workforce training, and sustainable practices—will be better positioned to thrive in an increasingly competitive and complex environment.