Let’s be real.

Buying a laser machine is not something you do every day. It’s a serious business decision. One wrong choice and you end up with slow production, wasted material, and daily frustration.

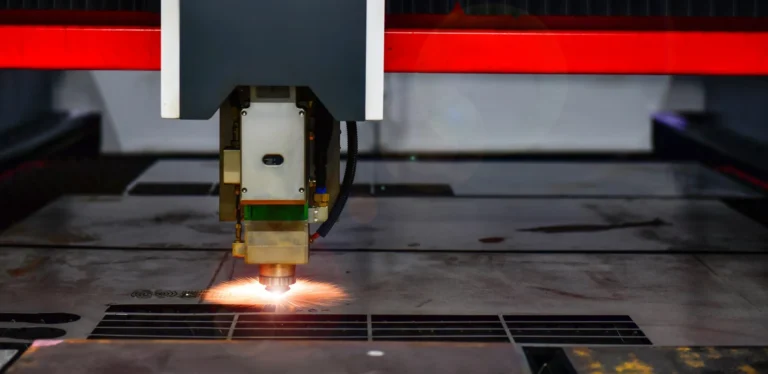

That’s why choosing the Right CO2 Laser Cutting Machine matters a lot more than people think.

The market is crowded. Everyone claims their machine is “best.” But honestly, not every machine fits every business. So instead of getting confused, let’s understand this step by step, in a simple and chill way.

Start With Your Actual Work Requirement

Before looking at machines, look at your own work.

Ask yourself clearly:

- What material will you cut most of the time?

- Acrylic, wood, MDF, leather, fabric, rubber?

- What thickness do you usually handle?

- How many hours will the machine run daily?

The Right CO2 Laser Cutting Machine depends fully on your workload. A small signage business and a large production unit need very different setups.

In fact, clarity here saves you money and regret later.

Understand Machine Power, Not Just Big Numbers

Many buyers get stuck on wattage. More watts, more power, more profit. Sounds simple, right?

Not exactly.

The CO2 Laser Cutting Machine has power that matches your material and thickness. Too low power slows work. Too much power increases cost and maintenance.

Think about:

- Cutting vs engraving needs

- Material thickness range

- Precision level required

Frankly, balanced power gives better long-term performance.

Check Cutting Area and Machine Size

Let’s be honest. Space matters.

The Right CO2 Laser Cutting Machine should fit both your job size and your workshop area.

Consider:

- The maximum sheet size you use

- Future work expansion

- Available floor space

- Ease of material loading

Buying a machine that’s too big or too small creates daily problems.

Software and Control System Should Be Simple

A machine is only as good as the person using it.

The Right CO2 Laser Cutting Machine comes with software that:

- Is easy to understand

- Supports common file formats

- Has smooth control features

- Does not confuse operators

In fact, complicated software slows production instead of improving it. Simple systems always work better on the shop floor.

Build Quality Makes a Big Difference

Photos don’t tell the full story. Real quality shows in daily use.

A strong Right CO2 Laser Cutting Machine has:

- Rigid body structure

- Smooth motion system

- Stable cutting performance

- Good cooling system

Also notice:

- Noise levels

- Vibration during operation

- Overall finishing

These small details decide machine life and cutting accuracy.

After-Sales Support Is Not Optional

Let’s be very honest here.

Machines can fail. Parts wear out. Settings need correction.

The Right CO2 Laser Cutting Machine comes with strong after-sales support:

- Proper installation

- Operator training

- Fast technical response

- Easy spare part availability

By the way, ask clearly who handles service. In-house support is always better than outsourced help.

Don’t Fall for Cheap Pricing Traps

Everyone likes discounts. But cheap machines often become expensive later.

The Right CO2 Laser Cutting Machine offers value, not just low price.

While comparing prices, think about:

- Maintenance cost

- Tube life

- Energy consumption

- Downtime risk

In fact, spending a little more initially can save a lot in the long run.

Visit the Manufacturer or Supplier If Possible

If you really want confidence, visit the place where the machine is built or tested.

Seeing the Right CO2 Laser Cutting Machine live helps you:

- Check cutting quality

- Understand machine strength

- Meet technical people

- Ask real questions

Manufacturers who avoid visits usually have something to hide.

Think About Future Growth Too

This is important and often ignored.

The Right CO2 Laser Cutting Machine should support:

- Higher workload in future

- New material types

- Upgrade options

- Business expansion plans

Frankly, buying only for today can limit tomorrow.

Final Thoughts

Choosing the Right CO2 Laser Cutting Machine is not about trends or sales talk. It’s about matching the machine to your real business needs.

Take time. Compare smartly. Ask uncomfortable questions.

When you choose right, the machine works for you, not against you. And honestly, that peace of mind is priceless.

FAQs

1. What is the Right CO2 Laser Cutting Machine for beginners?

A machine with moderate power, simple software, and good support is ideal.

2. Is higher wattage always better?

No. The Right CO2 Laser Cutting Machine depends on material and thickness.

3. How important is after-sales support?

Very important. Fast service reduces downtime and stress.

4. Should I visit the machine supplier before buying?

Yes, if possible. It builds trust and clarity.

5.Can one machine handle different materials?

Yes. The Right CO2 Laser Cutting Machine can handle multiple non-metal materials.