Selecting the Right Equipment

Choosing the right industrial equipment is crucial for operational efficiency, productivity, and safety. Equipment selection affects the quality of output, operational costs, and long-term ROI. Modern industries require machinery that is not only durable but also capable of integrating with digital systems for real-time monitoring and predictive maintenance.

The right equipment also enhances workplace safety. Machines with automated safety features, emergency shutdown systems, and proper ergonomics reduce accidents and downtime. Companies must consider both the immediate benefits and long-term operational impact when investing in equipment.

Types of Equipment

-

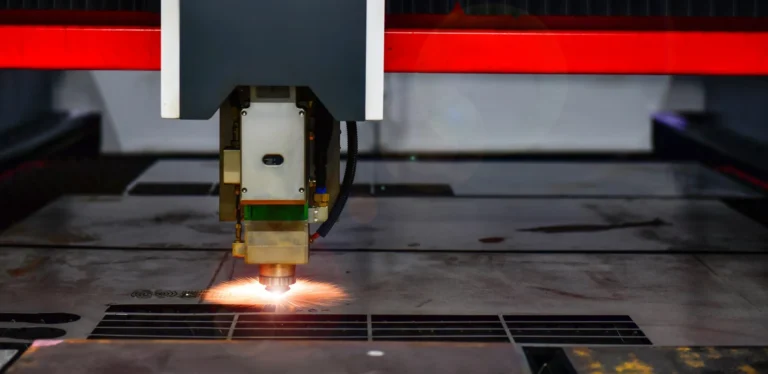

Machinery: CNC machines, lathes, presses, and automated assembly tools enhance precision and reduce manual labor. Advanced machinery is increasingly integrated with sensors and AI to improve performance.

-

Safety Equipment: PPE, fire suppression systems, and emergency shutdown mechanisms protect employees and minimize the risk of costly accidents.

-

Material Handling Equipment: Conveyors, forklifts, and automated storage systems improve workflow efficiency and reduce labor intensity.

-

Monitoring and Control Systems: Sensors, IoT devices, and SCADA systems provide real-time data on production metrics, helping companies prevent downtime and optimize performance.

Key Considerations When Purchasing Equipment

-

Durability and Reliability: Choose machinery designed for high workloads and harsh industrial environments.

-

Energy Efficiency: Energy-efficient equipment reduces operational costs and environmental impact.

-

Compliance with Standards: Ensure machinery meets industry safety and operational regulations.

-

Vendor Support: Reliable vendors provide warranties, maintenance services, and operator training.

Optimizing Equipment Performance

-

Preventive Maintenance: Regular maintenance schedules reduce the likelihood of equipment failure and extend machinery lifespan.

-

Operator Training: Well-trained employees can operate machinery efficiently, reduce errors, and ensure safety compliance.

-

Integration with Smart Technology: Connected equipment provides data on performance, enabling predictive maintenance and continuous optimization.

-

Workflow Alignment: Ensure equipment selection and placement align with production goals and facility design to maximize operational efficiency.

Case Examples

-

Ford Motor Company uses IoT-enabled equipment across its assembly lines to monitor performance, identify bottlenecks, and reduce downtime.

-

ABB Robotics integrates AI-driven predictive maintenance tools with industrial robots, increasing reliability and reducing repair costs.

-

Caterpillar employs advanced machinery and monitoring systems in heavy equipment manufacturing, improving efficiency and minimizing maintenance-related delays.

By strategically investing in high-quality industrial equipment and maintaining it effectively, companies can significantly improve operational efficiency, ensure workplace safety, and maximize long-term profitability.