Laser Soldering Machine

- Home

- »

- Laser Soldering Machine

Laser Soldering Machine Manufacturer in India

A laser soldering machine is usually introduced when regular soldering starts creating quality issues. In many production units, excess heat, weak joints, or damage to nearby components becomes a routine problem. Laser soldering is used to control these situations by applying heat only where soldering is actually needed.

At Laser Machine Manufacturers, laser soldering machines are developed after understanding how operators work on the floor. These machines are expected to run daily, sometimes continuously. Because of this, the design focuses more on stability and control rather than unnecessary complexity.

How Laser Soldering Machine Feels in Day-to-Day Use

Laser Soldering Machine works in a very focused way. The laser heats the solder point directly instead of spreading heat across the entire part. This difference becomes noticeable during repeated jobs.

After settings have been made, operators typically observe fewer corrections in their processes.

- Heat remains at the joint

- The components around the joint remain safe

- The solder connections look more even

Over a certain period, it enhances consistency.

|

Component

|

Description

|

|---|---|

|

Working Area |

100×100, 175×175, 220×220, 300×300 mm & Customized |

|

Laser Type |

Fiber Laser |

|

Laser Power |

20 W, 30 W, 50 W, 60 W, 100 W, 200 W |

|

Operating System |

Windows 10 |

|

Supported File Formats |

Working Voltage |

|

Working Voltage |

Single Phase 220–230 V / 50 Hz (Earthing Required) |

Where Laser Soldering Machines Are Commonly Used

A laser soldering machine is usually employed where the components are smaller or sensitive to thermal effects. Electronics, connectors, precision parts, etc., are some areas where this machine can be employed in an appropriate manner.

Therefore, due to better control of temperature, the parts do not easily change position or catch on fire. This helps during inspection and final assembly.

Before final assembly, many manufacturers use laser marking machines for identification and branding.

Performance During Long Production Hours

In real factory conditions, machines are rarely used for short periods. They run for hours. Laser soldering machines from Laser Machine Manufacturers are built with this expectation.

Once parameters are set, the output remains stable without constant operator involvement.

- Consistent results over long shifts

- Low variation between solder joints

- Fewer interruptions during the production process

This maintains a steady workflow.

Working Style of Laser Machine Manufacturers

Laser Machine Manufacturers concentrates on machines that work well in environments. Each laser soldering machine is built with balance and usability in mind.

Instead of pushing a fixed model, the company prefers to understand how the customer plans to use the machine.

- Built for regular industrial use

- Suggested based on application needs

- Availability of support during set-up and operation

This method prevents operational difficulties from arising.

For stronger bonding in industrial applications, a fiber laser welding machine is often recommended.

Talk to Us About Your Soldering Requirement

If your current soldering process feels inconsistent or difficult to control, a laser soldering machine from Laser Machine Manufacturers may help.

You can speak with the team to explain your application and working conditions. A suitable solution can then be discussed.

Member’s Arena

[Diamond Members]

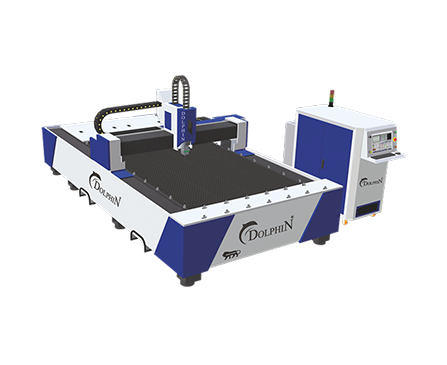

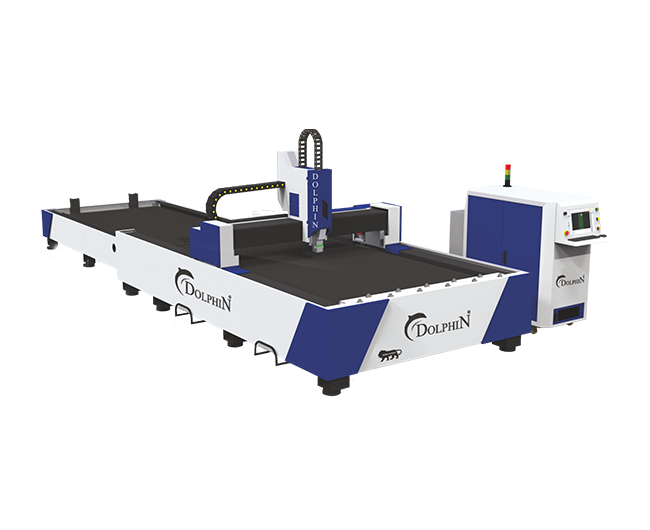

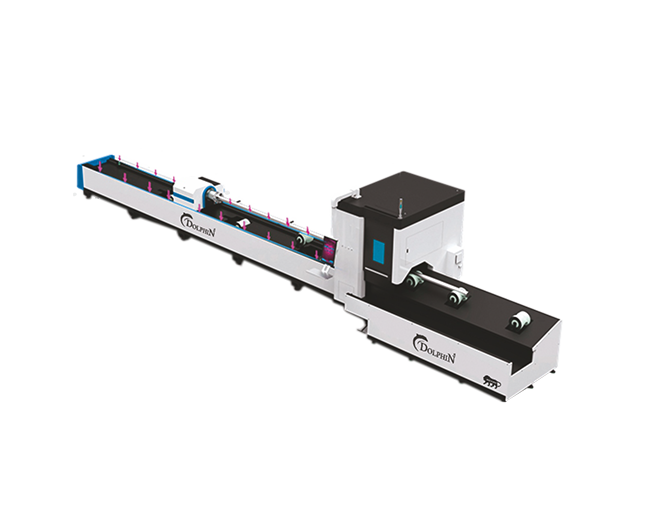

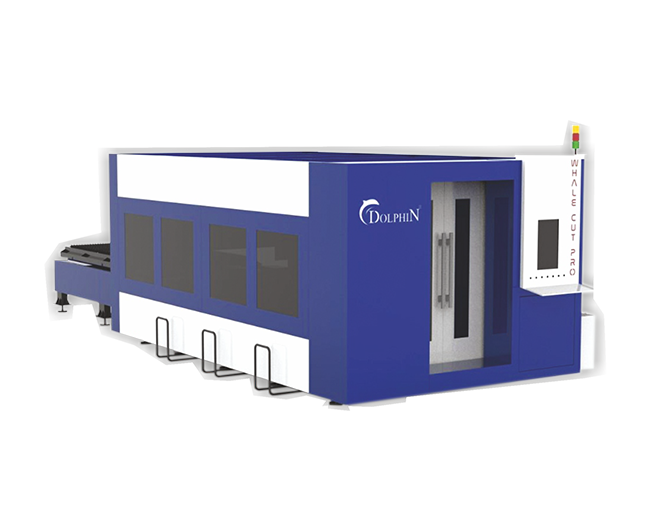

Dolphin Laser Machine PVT LTD

In the heart of Ahmedabad, a trailblazing venture, DOLPHIN LASER MACHINE PVT. LTD. established in 2015, stands as a premier Manufacturer and Exporter of all types of Industrial Laser Machines like Marking, Cutting, Engraving, Welding, and Cleaning. With a dedicated in-house R&D team and rigorous quality control adhering to ISO & CE standards, Dolphin Laser excels in crafting advanced systems using state-of-the-art technologies.

[Platinum Members]

Success Technologies

At Success Technologies, we pride ourselves on being at the forefront of innovation in the field of precision machinery and manufacturing solutions. Established with a vision to empower industries with cutting-edge technology, we have consistently delivered products that enhance productivity, precision, and efficiency.

Laser Soldering Machine

In the heart of Ahmedabad, a trailblazing venture, DOLPHIN LASER MACHINE PVT. LTD. established in 2015, stands as a premier Manufacturer and Exporter of all types of Industrial Laser Machines like Marking, Cutting, Engraving, Welding, and Cleaning. With a dedicated in-house R&D team and rigorous quality control adhering to ISO & CE standards, Dolphin Laser excels in crafting advanced systems using state-of-the-art technologies.

In the heart of Ahmedabad, a trailblazing venture, DOLPHIN LASER MACHINE PVT. LTD. established in 2015, stands as a premier Manufacturer and Exporter of all types of Industrial Laser Machines like Marking, Cutting, Engraving, Welding, and Cleaning. With a dedicated in-house R&D team and rigorous quality control adhering to ISO & CE standards, Dolphin Laser excels in crafting advanced systems using state-of-the-art technologies.

In the heart of Ahmedabad, a trailblazing venture, DOLPHIN LASER MACHINE PVT. LTD. established in 2015, stands as a premier Manufacturer and Exporter of all types of Industrial Laser Machines like Marking, Cutting, Engraving, Welding, and Cleaning. With a dedicated in-house R&D team and rigorous quality control adhering to ISO & CE standards, Dolphin Laser excels in crafting advanced systems using state-of-the-art technologies.

In the heart of Ahmedabad, a trailblazing venture, DOLPHIN LASER MACHINE PVT. LTD. established in 2015, stands as a premier Industrial Laser Machines

Our [Applications]

Excellence.

- 2D 3D Di

- Advertising

- Automobile

- Bearing

- Brass Parts

- Cable & Wire

- Copper Parts

- Cosmetics

- Cutting Tools

- Electronics

- Elevators

- Engineering

- Jewellery

- Fabrics & Jeans

- FMCG

Our Manufactures [Products]

Unmatched Quality. Unbeatable Value.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

FAQs

1. What is the main purpose of a laser soldering machine?

2. Is laser soldering appropriate for electronics work?

3. Can the machine be used daily in production?

4. Does laser soldering reduce damage to nearby parts?

5. How do I know if laser soldering fits my application?

Stay Connected with us on Facebook for New Updates.