Let’s be real. Buying a laser machine for wood cutting is not an everyday decision. It’s an investment. And if you choose the wrong one, daily work becomes stressful instead of smooth.

The market is full of options. Every seller says their machine is the best. But honestly, not every machine suits every business. That’s the point why understanding a handful of key factors prior to purchasing Laser Wood Cutting Machines can be of great help in terms of money, time, and hassle.

Therefore, let’s discuss this in an easy-going and relaxed manner.

Understand What Type of Wood You Will Cut

First things first. Not all wood is the same.

Before buying Laser Wood Cutting Machines, ask yourself:

- Will you cut MDF or plywood?

- Solid wood or thin veneer sheets?

- Light engraving or deep cutting?

In fact, different woods react differently to laser heat. The right machine depends on your regular material, not occasional jobs.

Decide Between Cutting and Engraving Needs

Let’s be honest. Many buyers get confused here.

There are Laser Wood Cutting Machines that are primarily intended for engraving, while there are others that can do cutting more effectively. If your task is mainly concerned with design, logos, or artwork, engraving becomes the main point. If you deal with furniture parts or panels, cutting power matters.

Be clear about:

- Depth of cut required

- Speed expectations

- Finish quality

- Clarity here avoids regret later.

Machine Power Matters, But Don’t Overdo It

Everyone talks about wattage. Higher wattage sounds impressive, right? But frankly, more power is not always better.

The right Laser Wood Cutting Machines should match your work:

- Thin wood needs less power

- Thick boards need more power

- Overpowered machines increase cost and maintenance

Balanced power gives better results and smoother operation.

Check the Working Area Size

This is something people often ignore.

Before buying Laser Wood Cutting Machines, check:

- Maximum wood sheet size you use

- Space available in your workshop

- Future expansion needs

Buying a machine that’s too small limits your work. Buying one too big creates space problems. Size matters more than people think.

Software Should Be Easy, Not Confusing

Let’s be real again. A powerful machine is useless if the software is hard to use.

Good Laser Wood Cutting Machines come with:

- Simple interface

- Easy file import

- Common format support

In fact, simple software reduces mistakes and saves time. Your operator should feel comfortable, not scared of buttons.

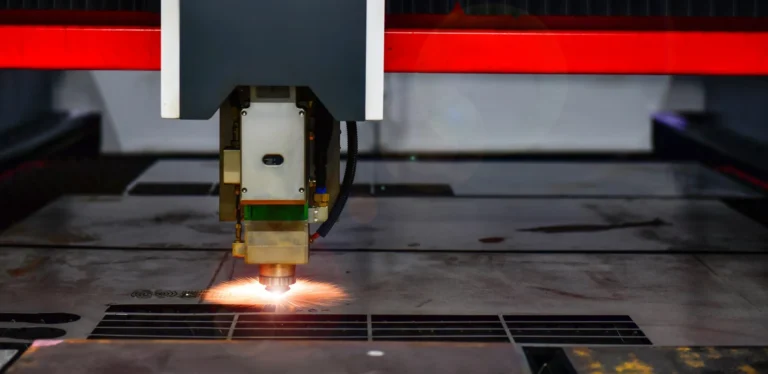

Build Quality Shows in Daily Use

Photos can be misleading. Real quality shows after months of work.

Strong Laser Wood Cutting Machines usually have:

- Solid frame

- Smooth motion system

- Stable cutting performance

Also notice vibration and noise. A stable machine gives cleaner cuts and longer life.

Ventilation and Smoke Control Are Important

Wood cutting creates smoke. That’s a fact.

Before buying Laser Wood Cutting Machines, check:

- Exhaust system quality

- Smoke removal efficiency

- Workshop ventilation setup

Poor ventilation affects cut quality and operator comfort. This is not something you should ignore.

After-Sales Support Is a Big Deal

Let’s be honest. Even the best machines can face issues.

Reliable Laser Wood Cutting Machines come with strong after-sales support:

- Installation help

- Operator training

- Quick technical support

- Easy spare parts availability

Ask clearly who handles service and how fast they respond. This matters a lot in real life.

Don’t Fall for Very Cheap Offers

Everyone loves discounts. But cheap machines often bring hidden costs.

Before choosing Laser Wood Cutting Machines, think about:

- Tube life

- Maintenance cost

- Downtime risk

In fact, a slightly higher-priced machine with good support usually performs better in the long run.

Think About Future Work Too

This is important. Your business will grow. Your work type may change.

Good Laser Wood Cutting Machines allow:

- Feature upgrades

- Better productivity

- Handling new designs

Buying only for today can limit tomorrow’s opportunities.

Final Thoughts

Buying Laser Wood Cutting Machines is not about following trends. It’s about choosing what fits your work, space, and budget.

Take your time. Ask questions. Compare smartly.

The selection of the right machine results in daily activities being smoother, quicker, and less of a strain. In all honesty, such a feeling of security is very valuable.

FAQs

1. Are Laser Wood Cutting Machines suitable for small workshops?

Indeed, there are several models that cater specifically to small and medium enterprises.

2. Is it possible to cut different kinds of wood with these machines?

Absolutely, Laser Wood Cutting Machines can cut MDF, plywood, and a variety of wood types.

3. Is laser cutting superior to manual wood cutting?

For precision and design work, yes. Laser cutting leaves behind neater results.

4. Is it necessary to regularly maintain Laser Wood Cutting Machines?

Not really. Usually, regular cleaning and a few basic checks are sufficient.

5. Should one purchase Laser Wood Cutting Machines?

Definitely. They find their worth in terms of productivity in the long run and their ability to create versatile designs.