Let’s be honest. Metal cutting used to be messy. Loud machines, rough edges, wasted sheets, and too much manual effort. Anyone who has worked in fabrication knows this pain. Things started changing when Metal Laser Cutting Machines came into the picture.

Today, these machines are not luxury items. They are practical tools for businesses that want speed, accuracy, and clean output. In fact, many workshops say the same thing after using them for a few months – work becomes smoother and less stressful.

Now, let us discuss in detail these machines’ capabilities and importance.

What Are Metal Laser Cutting Machines Precisely?

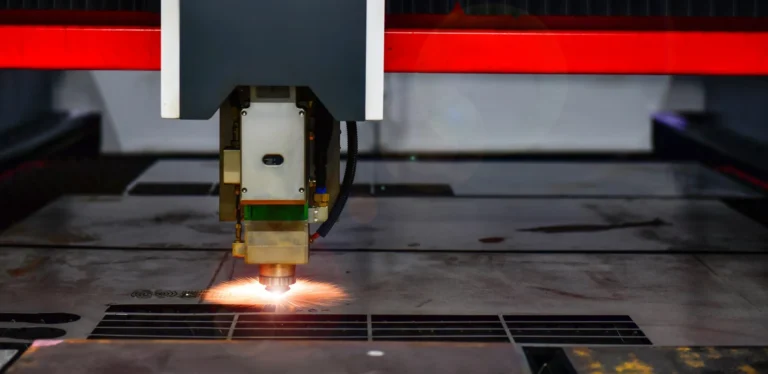

To put it in very simple terms, Metal Laser Cutting Machines are those which cut the metal sheets and plates by using a concentrated laser beam. The laser preferentially warms the metal and thus follows the path of a given pattern, resulting in a cut that is clean and sharp.

But a metal blade is not physically coming into contact with the metal. Hence, there is:

- Less vibration

- Better control

- More accuracy

By the way, these machines work on metals like stainless steel, mild steel, aluminum, and even copper in many cases.

Real Benefits of Metal Laser Cutting Machines

Let’s not sugarcoat things. Businesses invest in machines only when they see real value.

Better Accuracy in Daily Work

This is the first thing operators notice.

Metal Laser Cutting Machines produce cuts that are:

- Straight

- Clean

- Consistent

Even complex shapes and fine designs come out properly. There’s less need for rework, and that saves both time and money.

Faster Jobs, Less Waiting

Speed matters, especially when deadlines are tight.

With Metal Laser Cutting Machines, cutting time reduces a lot compared to traditional methods. Jobs that earlier took hours can now be completed much faster.

This helps in:

- Handling more orders

- Improving delivery timelines

- Increasing daily output

Frankly, faster work keeps customers happy.

Reduced Material Waste

Anyone who buys metal sheets knows how expensive raw material is.

Traditional cutting often wastes metal because of rough edges and wrong cuts. Metal Laser Cutting Machines minimize this issue. Since cuts are precise, sheet usage improves.

Over time, this saving becomes noticeable.

Cleaner and Safer Working Environment

Let’s be real. Old cutting methods create noise, sparks, and dust.

Laser cutting is comparatively cleaner. Metal Laser Cutting Machines create:

- Less noise

- Controlled cutting

- Better shop-floor safety

Operators feel more comfortable working long hours.

Important Features That Actually Matter

Not all features written in brochures are useful. Let’s focus on the ones that really help.

Stable Laser Source

The laser source decides performance.

Good Metal Laser Cutting Machines use reliable laser sources that:

- Maintain cutting quality

- Work consistently

- Last longer

Choosing the right power level is important. Too much power is not always necessary.

Strong Machine Structure

A rigid machine body keeps everything stable.

During operation, Metal Laser Cutting Machines face vibration and heat. A strong structure helps maintain accuracy, especially during long production runs.

This also improves machine life.

Simple Control System

Complicated software slows work. Everyone knows that.

Modern Metal Laser Cutting Machines come with control systems that are:

- Easy to understand

- Quick to operate

- Operator-friendly

Training time reduces, and mistakes also reduce.

Proper Cooling System

Laser cutting generates heat. If heat is not managed properly, performance drops.

That’s why reliable Metal Laser Cutting Machines include efficient cooling systems. This keeps components safe and ensures stable cutting quality throughout the day.

Common Applications of Metal Laser Cutting Machines

Now let’s talk about where these machines are actually used.

Sheet Metal Fabrication Units

This is the most common use.

Fabrication shops use Metal Laser Cutting Machines for:

- Panels

- Cabinets

- Brackets

- Frames

Accuracy and speed make daily work easier.

Automotive and Auto Parts Industry

Precision is critical here.

These machines are used to cut:

- Body parts

- Structural components

- Mounting brackets

Clean cuts help in proper assembly and reduce finishing work.

Electrical and Control Panel Manufacturing

Electrical industries need accurate metal parts.

Metal Laser Cutting Machines help in making:

- Electrical enclosures

- Control panels

- Mounting plates

This industry has been ruled by consistency.

Furniture and Interior Design

Metal furniture has become the trend setter these days.

Metal Laser Cutting Machines are being used by designers to make up-to-date designs, decorative panels, and sleek frames. The process of laser cutting not only opens up the path to innovative concepts but also reduces the effort involved in execution.

Industrial Machinery and Heavy Equipment

Even thick metal plates are handled well.

These machines support cutting of:

- Machine components

- Structural parts

- Industrial frames

High power and accuracy help meet heavy-duty requirements.

Why Businesses Trust Metal Laser Cutting Machines?

Let’s be honest. No one invests lakhs without reason.

Businesses trust Metal Laser Cutting Machines because:

- Quality improves

- Production becomes faster

- Manual effort reduces

- Long-term cost comes down

Once businesses adapt to laser cutting, going back feels outdated.

Final Thoughts

Metal Laser Cutting Machines are not about trends or show-off. They are about efficiency, accuracy, and smooth workflow.

If metal cutting is a regular part of your business, these machines can genuinely upgrade the way you work. Less stress, better output, and more control.

Honestly, this is what every company expects.

FAQs

1. Metal Laser Cutting Machines good for small workshops?

Definitely, there are lots of machines which can work great for small and medium businesses.

2. Is multiple metals cutting possible through a single machine?

Indeed, Metal Laser Cutting Machines are capable of cutting most kinds of metal.

3. Is laser cutting to plasma cutting?

Laser cutting is almost always preferred for precision and finish.

4. Do the operators need to be skilled for these machines?

Just basic training is needed for daily operation.

5. Are Metal Laser Cutting Machines a sound investment?

Certainly, savings and productivity in the long run make them worth it.